No. 290

- Despite widely-shared concern about their fragility, supply chains survived the COVID-19 shocks. In particular, the sophisticated international production networks (IPNs) in East Asia centered on machinery industries proved again to be robust and resilient.

- Although the US-China confrontation and geopolitical tension generate policy uncertainty in the trading regime, actual decoupling has so far been limited in scope. China continues to be an important economic partner for a wide range of businesses in Japan, the US, and other countries.

- Governments in ASEAN and East Asia must reduce policy risks as far as possible by defending the rule-based trading regime and help improve business environments for extending and deepening robust and resilient IPNs.

The sudden emergence of the COVID-19 pandemic triggered hot debates on the fragility of supply chains. The interruption of supply chains became a widely shared concern, and some called for immediate "reshoring," i.e., pulling production sites back to their home country. The May 16, 2020 issue of The Economist was even entitled "Goodbye Globalization." Others asserted the importance of ensuring the geographical extensiveness of supply chains to avoid "putting all eggs in one basket." Unfortunately, the discussion has been somewhat distorted or even misled by the complicated nature of COVID-19 shocks as well as geopolitical tension. This short article will list five "facts" that a series of empirical studies of monthly trade statistics and other information have largely confirmed for supply chains extending to East Asia and draw some policy implications.

First, COVID-19 did not kill supply chains. The three-shock approach has been explored by myself and my coauthors. The initial shocks were twofold: negative supply shocks due to the interruption of imports from China in February 2020 and positive demand shocks for personal protective equipment (PPE) with the spread of infections to other countries. Although people began to feel uneasy about the heavy reliance on supply chains, cross-border links were reactivated very quickly, in just a few months, thanks to market responses rather than government-led initiatives. While there was worry about negative demand shocks due to the worldwide recession, their impacts were limited thanks to unprecedented mitigation policies all over the world. The deepest trough of international trade was in the second quarter of 2020 for most countries. Although the cross-border movement of natural persons was severely restricted, business links were continuously maintained with the enhanced usage of communications technology. Contrary to initial concerns, globalization was not unwound.

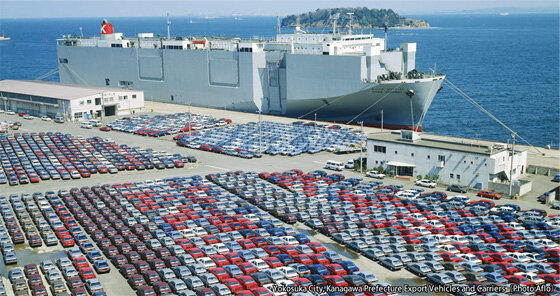

Second, the core of Factory Asia comprises international production networks (IPNs) represented by machinery industries. IPNs are a part of the general international production/consumption linkage or global value chains (GVCs) in which the sophisticated task-by-task international division of labor, or the second unbundling in Richard Baldwin's wording, is developed with relation-specific transactions. International trade within IPNs in East Asia was empirically proven to be more robust (unlikely to be interrupted) and resilient (likely to resume even if interrupted) than other types of international trade against the COVID-19 shocks. In order to set up IPNs, firms must invest from a long-run perspective and thus they would like to keep IPNs as long as the shocks are regarded as temporary. We also observed the robustness and resilience of IPNs in past crises such as the Asian Currency Crisis, the Global Financial Crisis and the Great East Japan Earthquake in a line of studies pioneered by Professor Ayako Obashi of Aoyama Gakuin University. In addition, positive demand shocks for remote work and stay-at-home products such as personal computers, displays, dishwashers, and electric handtools were strong in the COVID-19 pandemic, and East Asia aggressively took advantage of this to effect a swift recovery in exports to North America and Europe.

Third, geographically extensive supply chains including many countries and regions were more resilient than simple supply chains, particularly in facing negative supply shocks from upstream. There are two opposing forces here. On the one hand, extensive supply chains are more likely to be hit by a shock occurring somewhere in the world and may work as a shock transmission channel. On the other hand, once a shock comes, extensive supply chains can activate alternative back-up channels more easily and quickly. A series of empirical studies, including those by Professor Yasuyuki Todo of Waseda University and his coauthors, suggest that the latter force seemed to dominate during both the Great East Japan Earthquake and the COVID-19 pandemic.

Fourth, the US-China confrontation and other geopolitical tension put pressure on countries and private companies to "decouple". However, actual decoupling has so far been observed only for limited products such as those with sensitive technologies and rare earth/metals. Some countries in the Association of South-East Asian Nations (ASEAN) and South Asia have successfully attracted factories moving out of China, including Chinese-owned ones, but no mass exodus from China has been observed. Indeed, trade with China expanded during the COVID-19 crisis, and business with China is still very important for companies in Japan, the US, and other countries. Although the decoupling claim has generated policy risks for the private sector, many still believe that decoupling could be somewhat limited and not lead to the total shutdown of economic links.

Fifth, the rule-based trading regime has been particularly important for the private sector in operating IPNs in East Asia. COVID-19 caused many countries to introduce export restrictions for PPE and other essential goods, which reduced confidence in a stable business environment. Geopolitical tension also increased policy risks. What the private sector hopes for is reduced uncertainty in the trading regime.

The following policy implications can be drawn from these five facts.

The private sector was trying to optimize supply chains or IPNs even before COVID-19 by considering the tradeoffs between efficiency and risk management. The Japanese government may want to teach better risk management to the private sector and find chokepoints in supply chains to enhance their resiliency. These are not fundamentally within the government's purview, however, except perhaps when supply chains of very limited essential goods and sensitive technology products are involved.

To reduce policy uncertainty stemming from geopolitical tension is certainly one of the government's most important tasks. Rather than just policing private companies via export control, the government must help them collect necessary information on the scope of decoupling and work within the rule-based trading regime as far as possible even in the face of geopolitical tension. The definitions of "sensitive technologies" and "national security" must be clarified so that the private sector does not lose its dynamism.

Another thing that governments in Japan and other countries in Asia should do is further improve the business environment in collaboration with partner countries. This will provide the private sector with more choices and opportunities to extend and deepen IPNs, which is the most effective way to enhance the robustness and resilience of supply chains. In this context, it is important to ensure that mega free trade agreements (FTAs) such as the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the Regional Comprehensive Economic Partnership (RCEP) Agreement are living and evolving agreements in order to reduce policy risks and develop the rule-based trading regime.

IPNs are currently facing a number of challenges: COVID-19, geopolitical tension, digital technology, and environmental concerns. Although this article did not discuss the latter two, they may modify the basic mechanics of Factory Asia in the long run. However, in the short and medium run, IPNs will work continuously at the center of development strategies in ASEAN and East Asia.

Fukunari Kimura is Professor, Faculty of Economics, Keio University and Chief Economist, Economic Research Institute for ASEAN and East Asia (ERIA)