JIIA Strategic Comments (2021-06)

Papers in the "JIIA Strategic Commentary Series" are prepared mainly by JIIA research fellows to provide comments and policy-oriented analyses of significant international affairs issues in a readily comprehensible and timely manner.

The great power competition between the US and China casts a shadow over the international economy. As economics has come to be understood in the logic of national security, the international economic interdependence that has developed since the 1990s is being reconsidered. When looking at future international trends, it is essential to look at economies that reflect international power politics. With that in mind, this paper examines the reorganization of semiconductor supply chains, a current focus point, from the viewpoint of economic security.

The Economic Security of Semiconductors From the Viewpoints of Technology and Power

Behind the growing interest in cross-border semiconductor supply chains is the view that technology of a nation is the source of its power. First of all, the technology of a nation has been considered to be the basis of its power, or more directly, of its military strength and industrial competitiveness. There are technological gaps between nations, and nations that achieve technological innovation have a great advantage (at least temporarily) over other countries. It has been argued that nations that enable the development and manufacture of cutting-edge technologies and technological breakthroughs can produce cutting-edge weapons and become global powers.1 This traditional thinking can be seen in the current Biden administration as well. A report released by the Biden administration in June 2021, following reviews of semiconductor and other supply chains, stated that "semiconductors are essential to national security" and "are fundamental to the operation of virtually every military systems, including communications and navigations systems and complex weapons systems such as those found in the F -35 Joint Strike Fighter." 2

On the other hand, technology can give nations political influence in the inter-state relations.3 States and private companies with specific technologies that cannot be replaced in an international arena can exert influence as chokepoints. For example, the US government has eliminated the Chinese company Huawei from the UK's 5G network by "weaponizing networks" through export controls on semiconductors. In May 2020, the US government tightened its export control measures against Huawei, effectively banning the export of semiconductor-related products using technologies and manufacturing equipment originating in the US. As a result, the UK government, which had previously allowed Huawei to participate in some 5G networks, decided to remove Huawei from its 5G networks. The US influenced other countries' political decisions by hitting chokepoints in the semiconductor supply chain. The reason why semiconductor supply chains are now attracting attention from the viewpoint of economic security is that they are directly linked to a nation's power.

Two 'Verticals' and 'Horizontals'

There are two 'vertical' and 'horizontal' formulas in semiconductor supply chains. The first 'vertical' and 'horizontal' refer to 'integration' and 'division of labor,' respectively. Vertically-integrated companies operate entire supply chains from upstream to downstream. Therefore, it is possible to prevent the outflow of intellectual property (IP) by reserving (black-boxing) know-how and IP related to research, development and manufacturing within the company. Vertically-integrated companies include US-based Intel and AMD who have strengths in CPU sector. In the memory sector, the South Korea-based Samsung and SK Hynix are also vertically integrated. Vertically-integrated companies enjoy the benefits of black-boxing, but require substantial capital investment and maintenance costs. Closed systems can also lead to bloated organizations and stagnant technological innovation. It is hard for vertically-integrated companies to respond quickly to the rapidly changing semiconductor market.

On the other hand, the rise of horizontal divisions of labor is consistent with the remarkable development of international economic interdependence seen since the 1990s. Semiconductor supply chains are generally said to consist of four stages: development, design, manufacturing (pre-process), and assembly (post-process). There are reportedly about 600 manufacturing processes alone. In addition, there are a variety of special factors at play in the semiconductor industry, such as the uniqueness of the raw materials needed for manufacturing, the swift progress of technological innovation, the rapidly changing supply and demand balance, the distinctive economic cycle, prospective orders as a general business practice, constraints connected with resources such as water and electricity, and the need for highly-skilled human resources. Given these conditions, supply chains have been divided into production processes, and each process has been transferred to nations and regions with comparative advantages.

As the semiconductor industry grew, the development and design processes remained in the United States, but the low-value-added manufacturing processes (as they were then seen) were offshored overseas. As a result, East Asian companies that produce high-quality semiconductors by specializing in manufacturing with cheap labor entered the semiconductor industry. Horizontal semiconductor supply chains stretched across the Pacific, and a network of process-specific hubs concentrated in the US and East Asia. Currently, Qualcomm and Nvidia in the US are among the IP providers that develop and profit from selling IPs, and the US is the leader in the development process within semiconductor supply chains. Fabless companies that design chips include Qualcomm and Nvidia, as well as Broadcom and Texas Instruments in the US, Media Tech in Taiwan, and Huawei's chip subsidiary HiSilicon in China. Taiwan Semiconductor Manufacturing Co. (TSMC) is by far the unrivaled leader among foundries that manufacture electronic circuits, such as transistors, on the surface of silicon wafers (pre-process). However, there are also GlobalFoundries in the US and Semiconductor Manufacturing International Corporation (SMIC) in China. There are several assemblers involved in the post-process of cutting the wafers on which circuits were formed in the pre-process and then packaging and inspecting them. These include Taiwan's ASE Group, the US's Amkor, and China's Jiangsu Changjiang Electronics Technology (JCET). Recently, however, attention has been focused on the fact that supplies of semiconductors in the automotive industry have been disrupted due to Southeast Asian companies involved in the post-processing of semiconductors being hit hard by the COVID-19.4

In addition, the horizontal division of labor has been advancing in the semiconductor manufacturing equipment and materials industry. While companies such as Lam Research and Applied Materials (AMAT) in the US and Tokyo Electron in Japan are strong in the manufacture of etching equipment, Netherlands' ASML has an overwhelming presence in extreme ultraviolet (EUV) lithography machines. In addition, Japan's Disco has the world's top share in silicon wafer-cutting equipment. While Japan and the United States have strengths in the manufacturing equipment field, the Netherlands is currently dominating the field of EUV. In the materials field, Japanese companies are prominent. For example, Shin-Etsu Chemical is strong in the manufacturing of silicon wafers and photoresists, SUMCO in the manufactureing of silicon wafers, JSR and TOKYO OHKA in the production of photoresists, and Taiyo Nippon Sanso and Showa Denko in the production of etching gases. In this world of horizontal division of labor, each node in supply chains has pursued specialization and modularization and improved productivity by establishing a flexible system capable of responding to various demands.

The second 'vertical' and 'horizontal' refers to the forms of supply chain competition. A vertical supply chain competition is a competition between upstream and downstream supply chains, which includes competition for 'the most technologically sophisticated and financially profitable segments.5 This competition is often driven by the entry of emerging and developing countries into high-value-added processes dominated by developed countries. Emerging and developing countries that are concerned about being trapped in low-value-added areas of supply chains will promote industrial growth policies and try to climb up the supply chains.6 This corresponds to the vertical competition that arises when a company that has been in downstream processes enters the upstream processes in a supply chain. Vertical supply chain competition makes the largest customer the largest competitor. TSMC has previously stated that it will not move into other processes, such as design and post-process, in order to avoid competing with its own customers.

Horizontal supply chain competition, on the other hand, is competition between the same layers of supply chains. In short, this is competition among companies in the same process for orders from upstream companies. This includes competition among foundries over orders from fabless companies.

Pullback of semiconductor supply chains

Since the current competition between major powers has aroused interest in the security implications of each country's economic policies, even economics is understood through the logic of national security.7 There is a growing understanding that cross-border trade and technology transfers can bring disadvantages as well as benefits to one's country. Some people argue that the world has shifted from a win-win world to a zero-sum world.8 As a result, elements of international power politics are being reflected in international economic interdependence.

In this context, semiconductor supply chains are drawing attention because supply chain competition in the semiconductor industry has many security implications. From the standpoint that technology is the foundation of national power, especially its military strength and industrial competitiveness, the rise of countries of concern (and/or their companies with close ties to their governments or militaries) from the lower to the upper layers of supply chains is seen to potentially destabilize the existing international power balance. In particular, major powers recognize the importance of advanced technologies for military superiority and economic dynamism, so they seek to control advanced industrial sectors and prevent adversaries from doing the same.9 When the US government laments that the US' share of the global semiconductor market has declined from 37% to 12% over the past 20 years,10 it is apparently equating the decline in the US share of the global semiconductor market with the relative decline of its national power in the international arena. Above all, it has security concerns about the transfer of high-end semiconductor production functions to China. China's rise in supply chains is seen as a national security threat. The understanding that China pursues technological innovation through various means, legal and illegal, also strengthens this view. There are concerns that China, which is steadily making its own semiconductors, will disrupt the supply of semiconductors for foreign policy or national security reasons. This is why vertical supply chain competition causes economic security concerns.

Furthermore, horizontal supply chain competition also raises economic security concerns. If a particular process in a supply chain becomes an oligopoly, that process can turn into a chokepoint. Because considerable know-how is required in the semiconductor manufacturing process, the number of foundries capable of large-scale production of high-quality advanced semiconductors is extremely limited, and the barriers to entry into the foundry market are thus extremely high. In addition, since semiconductor manufacturing equipment makers have a firm hold on expertise regarding special manufacturing equipment, this market has become oligopolistic. This is why TSMC, which has an overwhelming presence in the pre-process of semiconductor manufacturing (especially in advanced pre-processing), and ASML, which holds the top share globally in EUV, are drawing attention. Chokepoints are garnering much attention because of the concern that nations will be able to attack chokepoints in semiconductor supply chains by 'weaponizing networks' in order to influence other nations' political decisions, as the US itself has done. Of course, the disruption of supply chains due to COVID-19 has raised concerns about the vulnerability of supply chains having no alternatives for their chokepoints.

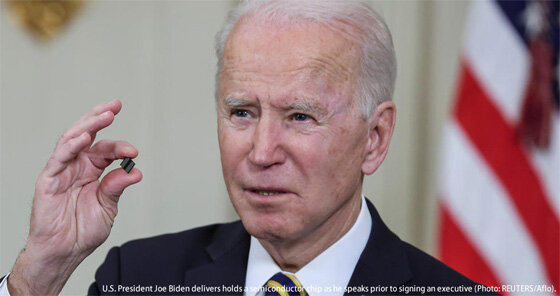

In this way, the momentum to reorganize semiconductor supply chains rose in the US, prompting moves to pull back existing supply chains that have stretched across national borders in pursuit of economic rationality. The Interim National Security Strategic Guidance, released in March 2021, pointed out the necessity of rebuilding supply chains for critical goods for an economic recovery. 11 The first step in doing so was a review of supply chains. In February, President Biden issued Executive Order (EO) 14017, ordering the relevant US government agencies to review supply chains in four industries, including the semiconductor industry, and report the results within 100 days. 12 According to Peter Harrell, senior director for international economics and competitiveness at the National Security Council (NSC), the EO aimed at moving from "the business of reacting to supply chain crises as they arise" to "the business of preventing future supply chain problems."13 In accordance with the EO, the review process examined semiconductor supply chains through essential segments such as design, etching, fabrication, assembly, test and packaging (ATP), as well as advanced packaging, materials and manufacturing equipment. These processes correspond to the processes of semiconductor supply chains described in this paper. Based on the review, the report, released on June 8, identified "risks that encompass most of the identified threats to semiconductor supply chains", among them fragile supply chains and malicious supply chain disruptions, and made policy recommendations to "address the current semiconductor shotage and the risks identified in the report."14 In addition, on September 24, the US government requested that domestic and foreign semiconductor companies provide information on semiconductor supply chains.15 Officially, this request for information constituted "a voluntary survey of industry participants."16 However, Secretary of Commerce Gina Raimondo reportedly "warned industry representatives that she might invoke the Defense Production Act or other tools to force their hands if they don't respond."17 The request for information included the provision of company trade secrets. The US government's approach indicates its aggressive intention to make further intrusive reviews of semiconductor supply chains. The Japanese government also pledged to analyze semiconductor supply chains in its Action Plan of the Growth Strategy approved by the Cabinet on June 18.18

In parallel with these reviews of semiconductor supply chains, focus has been placed on nations' efforts to foster advanced semiconductor industries domestically. When economics is understood in the logic of national security, the way markets operate, especially in strategically important sectors, can change. Some nations "have chosen not to look to open markets," "opting instead to tie-up long term supplies through state-led contracts with other governments."19 There are also arguments that industrial subsidies and government intervention are justified in situations where supply is dependent on a monopoly supplier that could become the target of intervention by adversary governments.20

The FY2021 National Defense Authorization Act was enacted in the US in January 2021, and Article 9902 of that Act states that the Department of Commerce will launch a program that "provides Federal financial assistance to covered entities to incentivize investment in facilities and equipment in the United States for semiconductor fabrication, assembly, testing, advanced packaging, or research and development."21 President Biden has pledged $50 billion to the program,22 and in June the Senate passed the US Innovation and Competition Act that gives legal backing to such investment.23 In addition, Europe, which lagged behind in semiconductor manufacturing, is not hiding its ambition to develop a cutting-edge semiconductor industry. In March 2021, the Digital Compass was announced with an ambitious goal of capturing 20% of the global value-based market for advanced and sustainable semiconductor manufacturing by 2030. 24 In September, European Commission President von der Leyen announced a plan to create the most up-to-date European semiconductor ecosystem. The initiative is aimed at ensuring supply chain security by coordinating EU and Member State investments and creating new markets for innovative technologies. In addition, von der Leyen has been active in pushing for the passage of the European Chips Act.25 The Japanese government also has shown an aggressive attitude toward developing semiconductor manufacturing. The Action Plan of Growth Strategy clearly states, in the subchapter 'Ensuring technological superiority from the perspective of economic security,' that "(n)ew projects will be created to provide strong support for the practical application of advanced technologies that are important from the perspective of strengthening economic security in the fields of...supercomputers/semiconductors" under the banner of 'Technology development'.26

However, it is not realistic for a single country to develop the world's most advanced semiconductor industry. Readying fully-outfitted factories and facilities, accumulating know-how, and developing human resources entails enormous economic costs and considerable lead time. In addition, closed supply chains completed within a single country are not suited to the semiconductor industry, where technological innovation is progressing rapidly. Even for ASML, which is dominant in the market for EUV lithography systems, open innovation is the key to technological success. Therefore, governments are focusing on attracting overseas suppliers of advanced semiconductors. The US government, for example, has been lobbying TSMC and Samsung, and TSMC has said it will build a manufacturing facility in Arizona that will begin operations by 2024. The state of Arizona responded positively, setting up a consortium of universities, companies and the state government. In Europe, the EU has announced subsidies to attract Intel, TSMC and Samsung, and TSMC has said it is considering setting up a plant in Germany. The Japanese government is also focusing on attracting TSMC and, according to media reports, plans are under way to attract TSMC to Tsukuba City in Ibaraki Prefecture and to Kumamoto Prefecture. The Japanese government clearly states in its Action Plan for Growth Strategy that "since there is a high concentration of production bases for advanced semiconductors internationally, we will urgently promote initiatives comparable to those in other countries and promote the location of production bases for advanced semiconductors in Japan to build a reliable supply system."27 In this way, TSMC, which is unrivaled in cutting-edge pre-process, has become a target of solicitations by many countries.

In addition, export controls are also an important tool for semiconductor supply chain pull-back. Domestic products and technologies essential to the manufacturing of advanced semiconductors are of the utmost importance for many countries, and how to achieve both open innovation and technology protection is critical. It is expected that the US Department of Commerce will seek to add state-of-the-art lithography tools such as EUV masks, reticles and pellicles for semiconductor manufacturing to the emerging technology export controls under Section 1758 of the Export Control Reform Act (ECRA). The Commerce Department has said it will be coordinating with other countries through international export control regimes such as the Wassenaar Arrangement to implement export controls on these emerging technologies. While the Commerce Department's position is certainly in accordance with Section 1758 of the ECRA, some critics in the US have argued that emerging technology export controls are too late to be effective28. The Commerce Department's approach is aimed at leveling the playing field of export controls, and the US government's position suggests that it wants to avoid unilateral regulation placing US companies and research institutions in an unfair position in the international arena.

Plurilateralism and New Supply Chain Competition

A single country cannot both rewind existing cross-border supply chains and build new ones. This is because it is unrealistic to acquire all of the facilities, equipment, materials, and economic and human resources required for semiconductor manufacturing in just a single country. As a result, a semiconductor supply chain pullback means building supply chains within a system consisting of several countries including one's own. Particularly noteworthy is the development of plurilateral measures. Within a small set of countries sharing common interests and values, semiconductor supply chain reviews and industry development are being pursued.

In September 2021, the 2nd Quad Summit held among Japan, the US, Australia and India announced the launch of the Semiconductor Supply Chain Initiative to map capacity, identify vulnerabilities, and bolster supply-chain security for semiconductors and their vital components.29 At the September 29 inaugural meeting of the US-EU Trade and Technology Council (US-EU TTC), one of the main agendas was the pullback of semiconductor supply chains. In addition to coordinating export controls between the US and the EU, they reaffirmed their commitment to building a partnership for rebalancing global semiconductor supply chains, identifying gaps in the semiconductor value chain, and strengthening their domestic semiconductor ecosystems. They also expressed their shared aims of avoiding a subsidy race and the risk of crowding out private investments and of reducing existing strategic dependencies throughout supply chains, especially through diversification of supply chains and increased investment.30 In this way, efforts are being promoted to pull back semiconductor supply chains into their own systems, based on pluralistic measures carried out by a small set of countries. The steps actually being taken are identifying vulnerabilities through supply chain mapping and cooperating on measures that contribute to industrial development.

However, such pullbacks of supply chains into their own systems do not always proceed linearly and smoothly. Indeed, there has already been a shift in strategy for vertically integrated firms. Under CEO Pat Gelsinger, who took office in February 2021, Intel announced a new strategy called IDM 2.0. The strategy consists of three pillars: (1) to continue in-house processor manufacturing and enhance production capacity; (2) to increase outsourcing; and (3) to start a global foundry business31. Among these, the start of a foundry business received the most attention. Intel, one of the largest vertically integrated semiconductor companies in the world, announced its ambition to enter the field of horizontal divisions of labor (the foundry business). The company said it would consider building new plants in Arizona and Europe, and groundbreaking ceremonies were already held on September 24 in Arizona for two semiconductor manufacturing facilities aiming to start operation in 2024. Intel's new strategy could lead to a vertical supply chain competition in the opposite direction. In the past, vertical competition was for upstream supply chains, which was regarded as a high-value-added process, but the new vertical competition is for the downstream manufacturing process. Intel will compete with TSMC and Samsung in the foundry business. However, some predict that Intel will have a hard time competing with TSMC. This is because, while Intel has made little headway in the development of 7-nanometer technology, TSMC can already mass-produce 5-nanometer products and is the leader in microfabrication. It is not easy to predict the future of the vertical supply chain competition triggered by Intel.

Furthermore, the vertical supply chain competitions in the opposite direction can force companies to reconsider their specialization strategies, which has been the premise of the horizontal division of labor in the supply chains. . There are already signs of this happening. As mentioned above, the Japanese government has been aggressive in inviting TSMC to Japan. TSMC is reportedly expected to start joint research and development of three-dimensional integrated circuits (3DIC) in Tsukuba City, Ibaraki Prefecture, together with a Japanese chip packaging provider, a materials supplier, and a cutting device maker.32 3DIC corresponds to the post-process of semiconductor manufacturing. It is clear that TSMC, which had previously denied moving beyond the pre-process in order to avoid vertical supply chain competitions, intends to enter the post-process market and will consequently be in a competitive relationship with the ASE Group in the post-process market. In addition, TSMC is reportedly planning a semiconductor joint venture in Kumamoto with the Sony Group and DENSO.33 Sony is a major player in image sensors, as is DENSO in automotive components. This suggests that TSMC is interested in the business surrounding sensors in anticipation of the age of autonomous driving. A similar reason may be behind TSMC's plan to establish a plant in Germany. Even TSMC, the largest foundry, is rethinking its specialization strategy, aspiring to move into other processes and associated businesses in semiconductor supply chains. Specialization strategies, which have been the premise of horizontal supply chains, appear to be wavering.

Conclusion

In the era of great power competition, we see countries making moves to shift the center of gravity of international economic interdependence into their own systems. The most striking expression of this is the restructuring of semiconductor supply chains. This paper examined how governments in Japan, the US and Europe seek to pull back semiconductor supply chains into their own systems. Governments use a variety of tools such as subsidized industrial development, but the most distinctive today is the use of plurilateral measures based on cooperation with a small set of nations that share common interests and values. The governments of Japan, the US and Europe appear to be working hard to review supply chains and implement efficient industrial policies based on pluralistic measures. Moreover, if semiconductor supply chains are further reviewed and specific risks are identified, goods or technologies subject to export control will be added to reduce such risks. Such controls will be based on plurilateral measures that complement the existing international export control regimes.

The current supply chain restructuring is largely due to increased focus on manufacturing processes (especially microfabrication) in semiconductor supply chains. Companies that perceive the coming supply chain structures and transformations in industry are rethinking their existing semiconductor strategies, triggering new supply chain competition. The Kishida Cabinet, inaugurated on October 4, 2021, established Japan's first Minister for Economic Security. This shows that the administration of Prime Minister Fumio Kishida is placing importance on economic security. The Japanese government will be required to take difficult steps to reconstruct supply chains based on pluralistic measures on the presumption of new supply chain competition.

*After this paper was written, TSMC announced on October 14 that it will be building a new plant in Kumamoto Prefecture.

(This is an English translation of a paper originally published in Japanese on October 11, 2021.)

1 Robert Gilpin, War and Change in World Politics (Cambridge: Cambridge University Press, 1981); and John J. Mearshimer, The Tragedy of Great Power Politics (New York: W. W. Norton & Company, 2001).

2 The White House, Building Resilient Supply Chains, Revitalizing American Manufacturing, and Fostering Brough-Based Growth: 100 - Day Reviews under Executive Order 14017, June 2021, p. 25.

3 For a representative discussion of power from the perspective of influence (power relations). See Albert O. Hirschman, National Power and the Structure of Foreign Trade, extended ed. (University of California Press, 1980) .

4 "Handotai-kiki, Dai Ni Ha Torai: Tounan Ajia Shingenchi Korona Kakudai Hibiku," Nikkan Kogyo Shimbun (Sep. 21, 2021), (in Japanese).

5 Parag Khanna, Connectography: Mapping the Global Network Revolution (Widenfeld & Nicolson, 2017), p. 160.

6 Satoshi Inomata, Gurobaru Baryuche-n: Shin Nanbokumondai eno Manazashi (Tokyo: Nihon Keizai Shimbun Sha, 2019), (in Japanese).

7 Robert Blackwill and Jennifer M. Harris, War by Other Means: Geoeconomics and Statecraft (Cambridge: Harvard University Press, 2016), pp. 24-25.

8 Gideon Rachman, Zero-sum World: Politics, Power and Prosperity after the Crash (London: Atlantic Books, 2012).

9 Darren Lim, "The US, China, and ' Technology War '," Global Asia (Mar. 2019), Vol. 14, No. 1, pp. 8 -13, esp. p. 9.

10 The White House, Fact Sheet: Bidden-Harris Administration Announcements Supply Chain Disruptions Task Force to Address Short-Term Supply Chain Discontinuities, June 8, 2021. https://www.whitehouse.gov/briefing-room/statements-releases/2021/06/08/fact-sheet-biden-harris-administration-announces-supply-chain-disruptions-task-force-to-address-short-term-supply-chain-discontinuities/

11 John R. Biden, Jr., Interim National Security Strategic Guidance (Washington, the White House, March 2021).

12 Executive Order 14017, America's Supply Chains, February 24, 2021.

13 Press Briefing by Press Secretary Jen Psaki, Deputy Director of the National Economic Council Sameera Fazili, and Senior Director for International Economics and Competitiveness Peter Harrell, February 24, 2021, White House Press Briefing, Feb 24, 2021, https://www.whitehouse.gov/briefing-room/press-briefings/2021/02/24/press-briefing-by-press-secretary-jen-psaki-deputy-director-of-the-national-economic-council-sameera-fazili-and-senior-director-for-international-economics-and-competitiveness-peter-harrell/

14 The White House, op.cit., June 2021.

15 Bureau of Industry and Security, "Notice of Request for Public Comments on Risks in the Semiconductor Supply Chain," Federal Register (vol. 86, no. 183), Sep. 24, 2021, pp. 53031 -53033.

16 Sameera Fazili and Peter Harrell, When the Chips Are Down: Preventing and Addressing Supply Chain Disruptions (The White House, Sep. 23, 2021). https://www.whitehouse.gov/briefing-room/blog/2021/09/23/when-the-chips-are-down-preventing-and-addressing-supply-chain-disruptions/

17 Jenny Leonard, "White House Weighs Invoking Defense Law to Get Chip Data," Bloomberg, Sep. 24, 2021. https://www.bloomberg.com/news/articles/2021-09-23/white-house-weighs-invoking-defense-law-to-get-chip-supply-data

18 Action Plan of the Growth Strategy (June 18, 2021) p. 25.

19 Blackwill and Harris, op.cit., pp. 42 -43.

20 "Trade: Message in a Bottleneck," The Economist, Apr. 3, 2021.

21 FY 2021 National Defense Authorization Act., Sec. 9902.

22 The White House, Fact Sheet: The American Job Plan, Mar. 31, 2021.

23 The House's CHIPS Act has not been passed as of this writing.

24 European Commission, 2030 Digital Compass: the European Way for the Digital Decade (Brussels, Mar. 9, 2021).

25 2021 State of the Union Address by President von der Leyen, Strasbourg, Sep. 15, 2021.

26 Growth Strategy Action Plan (June 18, 2021) p. 23.

27 Action Plan for Growth Strategy, p.26.

28 Emma Rafaelof, "Unfinished Business: Export Control and Foreign Investment Reforms," U.S.-China Economic and Security Review Commission Issue Brief, June 1, 2021.

29 The White House, Fact Sheet: Quad Leaders' Summit, Sep. 24, 2021. https://www.whitehouse.gov/briefing-room/statements-releases/2021/09/24/fact-sheet-quad-leaders-summit/

30 The White House, U.S.-EU Trade and Technology Council Inaugural Joint Statement, Sep. 29, 2021. https://www.whitehouse.gov/briefing-room/statements-releases/2021/09/29/u-s-eu-trade-and-technology-council-inaugural-joint-statement/

31 Intel, Intel CEO Pat Gelsinger Announces ' IDM 2.0 ' Strategy for Manufacturing, Innovation and Product Leadership, Mar. 23, 2021. https://www.intel.com/content/www/us/en/newsroom/news/idm-manufacturing-innovation-product-leadership.html#gs.cfvfcp

32 Masaya Sato "TSMC Tie-up Puts Spotlight on Japan's Hidden Chip Champions," Nikkei Asia, June 15, 2021. https://asia.nikkei.com/Business/Tech/Semiconductors/TSMC-tie-up-puts-spotlight-on-Japan-s-hidden-chip-champions

33 "Soni-TSMC no Keikaku Shinten: Handoutai Gouben, Denso Sanka," Nikkan Kogyo Shimbun (August 26, 2021), (in Japanese).